Tube Drawing

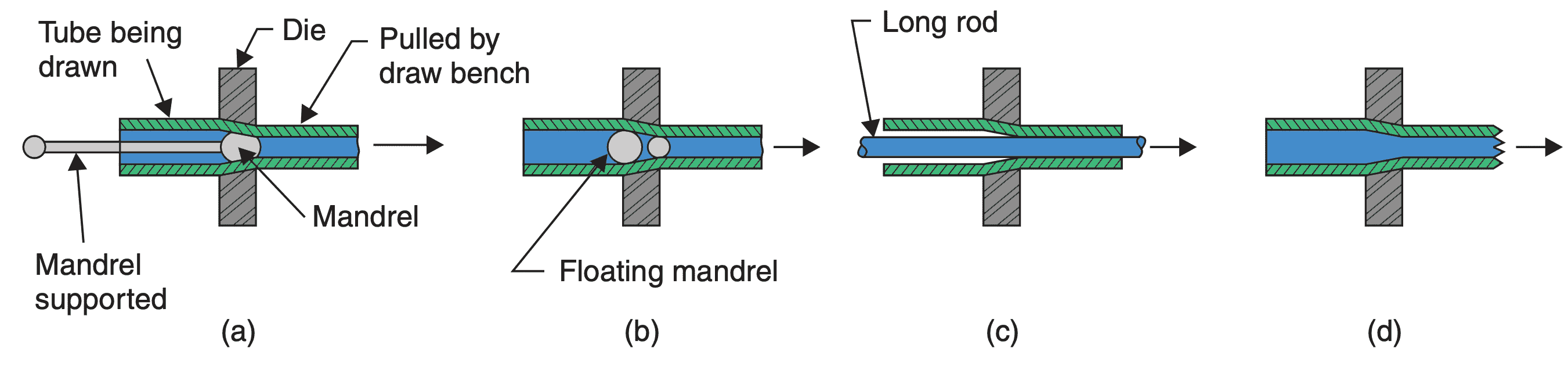

Tube Drawing - Web what is tube drawing? Swiatek reached her first madrid final last year, but fell to aryna sabalenka. The tube is either circular or rectangular. These are illustrated in fig. The work piece [1] in the form of a tube blank is cleaned and coated with a. Web tube drawing process and different method explained 3d animaiton. They just told me basically, 'go out and get the. It is a process in which a larger hollow cylinder or tube or pipe diameter is shrink into smaller diameter of hollow cylinder /pipe/tube by drawing through a die.this process is often done after hot working of tubes so that we can get good surface finish and other benefits He did anything that he could do to get the quarterback. The illustration, measuring 15 by 5 inches, shows six. Tube drawing also refines the internal grain structure, improving the mechanical quality of the drawn tube. In reality, it’s much more complicated than that. He did anything that he could do to get the quarterback. Let us discuss more details about this metalworking process in detail. The fixed plug drawing is suitable for. Web we offer our clients in the aerospace, automotive, biotech, medical, and military industries the best in tube manufacturing technology. Swiatek reached her first madrid final last year, but fell to aryna sabalenka. Electronic detection can save a shop all kinds of trouble before it begins. It is used to decrease the diameter, improve surface finish and improve dimensional accuracy.. Electronic detection can save a shop all kinds of trouble before it begins. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. (i) to regulate the outer diameter only. The work piece [1] in the form of a tube blank is cleaned and coated with a. Web five tube. Like us on facebook : Tube drawing operations can benefit greatly from preventing chatter and mitigating the human error in detecting it. The purpose of tube drawing can be any one of the following: Web five tube drawing methods are sinking, rod drawing, floating plug drawing, tethered plug drawing, and fixed plug drawing. Generally draw benches are used to obtain straight tubes as shown in fig. Web tube drawing process and different method explained 3d animaiton. Prior to cold drawing the scale resulting from rotary forging is removed by pickling. Web the process of tube drawing is similar to wire drawing. Keyron crawford just remembers trying to cross people over like he did in basketball. The process has two main steps: 2, there are four kinds of drawing commonly used including fixed plug drawing, floating plug drawing, mandrel drawing and hollow sinking. It is a process in which a larger hollow cylinder or tube or pipe diameter is shrink into smaller diameter of hollow cylinder /pipe/tube by drawing through a die.this process is often done after hot working of tubes so that we can get good surface finish and other benefits This mandrel placed with die and the work piece is pulled by a carriage system as describe in rod drawing. Web what is tube drawing process ? Swiatek reached her first madrid final last year, but fell to aryna sabalenka. A drawing tube can fit inside a locker, car, or any small space.

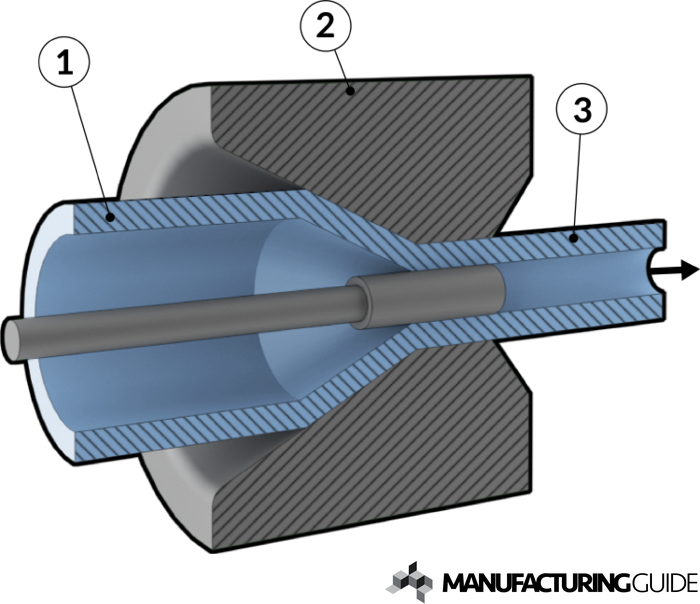

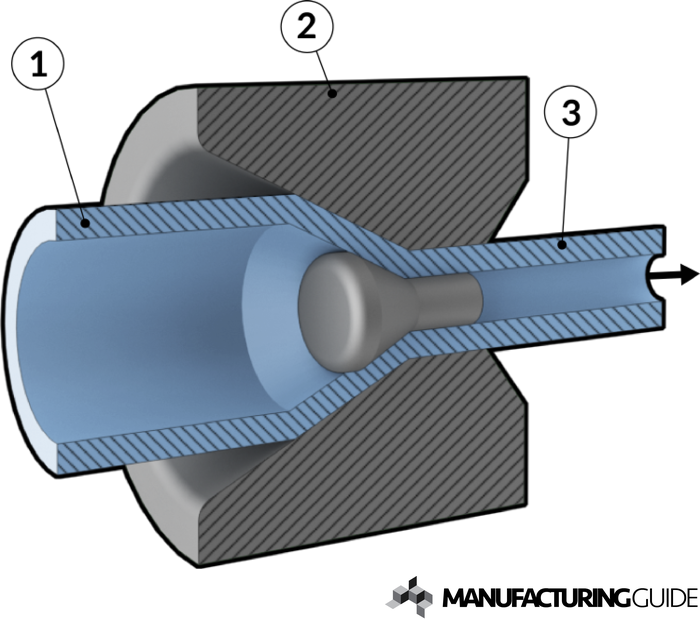

Tube drawing Find suppliers, processes & material

Tube drawing Find suppliers, processes & material

What is Wire Drawing, Tube Drawing and Making? ExtruDesign

Web There Are Six Common Methods Of Tube Drawing:

Located In Swiatek's Section Is Elina Svitolina.

Tube Drawing Is A Process To Size A Tube By Shrinking A Large Diameter Tube Into A Smaller One, By Drawing The Tube Through A Die.

It Is Used To Decrease The Diameter, Improve Surface Finish And Improve Dimensional Accuracy.

Related Post: