Tolerances On Engineering Drawings

Tolerances On Engineering Drawings - Concentricity is a very complex feature because it relies on measurements from derived median points as opposed to a surface or feature’s axis. Web what is a tolerance? We are going to look at what are tolerances and reasons for size variations. Other measured values (such as temperature, humidity, etc.); Limitations of tolerancing before gd&t. Web tolerance is the total amount a dimension may vary and is the difference between the upper (maximum) and lower (minimum) limits. If you take a look at an engineering drawing, you will notice that there are always limits, or tolerances, placed on a dimension. I discuss tolerances on engineering drawings. However, perfect parts don’t exist in. Furthermore, we are going to learn. Because it is impossible to make everything to an exact size, tolerances are used on production drawings to control the parts. Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Why does the designer do this? Classification and symbols of geometric tolerance characteristics. Web geometric dimensioning and tolerancing is. Web in this video, we are going to learn about tolerances in engineering drawing! Currently, we have 16 symbols for geometric tolerances, which are categorized according to the tolerance they specify. Web an engineering drawing may include general tolerances in the form of a table or just a little note somewhere on the drawing (e.g. Web gd&t is a way. When a part is designed, the cad model is designed exactly how we want the part to be. Important information regarding asme pdfs. They can be applied to several conditions, including linear dimensions, angular dimensions, external radius, chamfer heights, etc. Because it is impossible to make everything to an exact size, tolerances are used on production drawings to control the. Furthermore, we are going to learn. They can be applied to several conditions, including linear dimensions, angular dimensions, external radius, chamfer heights, etc. A measured value or physical property of a material, manufactured object, system, or service; Currently, we have 16 symbols for geometric tolerances, which are categorized according to the tolerance they specify. Web gd&t is a way of describing the dimensions and tolerances that’s different from traditional coordinate measurement plus/minus tolerancing. It’s the basics of engineering tolerance. Web an engineering drawing may include general tolerances in the form of a table or just a little note somewhere on the drawing (e.g. A great way to find all the corresponding engineering tolerances to specific measurements is by using a limits & fits calculator. I discuss tolerances on engineering drawings. Scope of the applying tolerances. Web engineering tolerance is the permissible limit or limits of variation in: When a part is designed, the cad model is designed exactly how we want the part to be. True position theory (size value in rectangular. Our online calculator streamlines this process and provides a detailed final result immediately. Geometric tolerances are specified using symbols on a drawing. Web what is a tolerance?

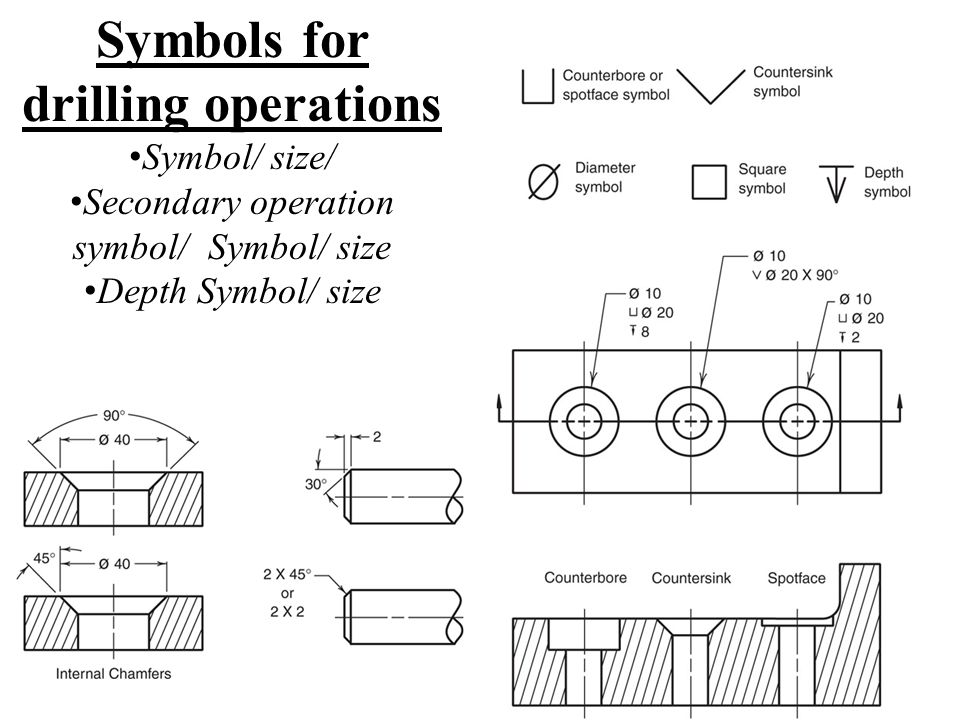

Examples of Determining the Tolerance on an Engineering Drawing? ED

Engineering Tolerances Design Learning Objects

Types Of Tolerance In Engineering Drawing at GetDrawings Free download

Other Measured Values (Such As Temperature, Humidity, Etc.);

Classification And Symbols Of Geometric Tolerance Characteristics.

Concentricity Is A Very Complex Feature Because It Relies On Measurements From Derived Median Points As Opposed To A Surface Or Feature’s Axis.

Web For Example, A Hole Is Located From An Edge By A Certain Amount (A Linear Dimension), Plus Or Minus A Smaller Amount (The Tolerance).

Related Post: