Tolerances In Drawings

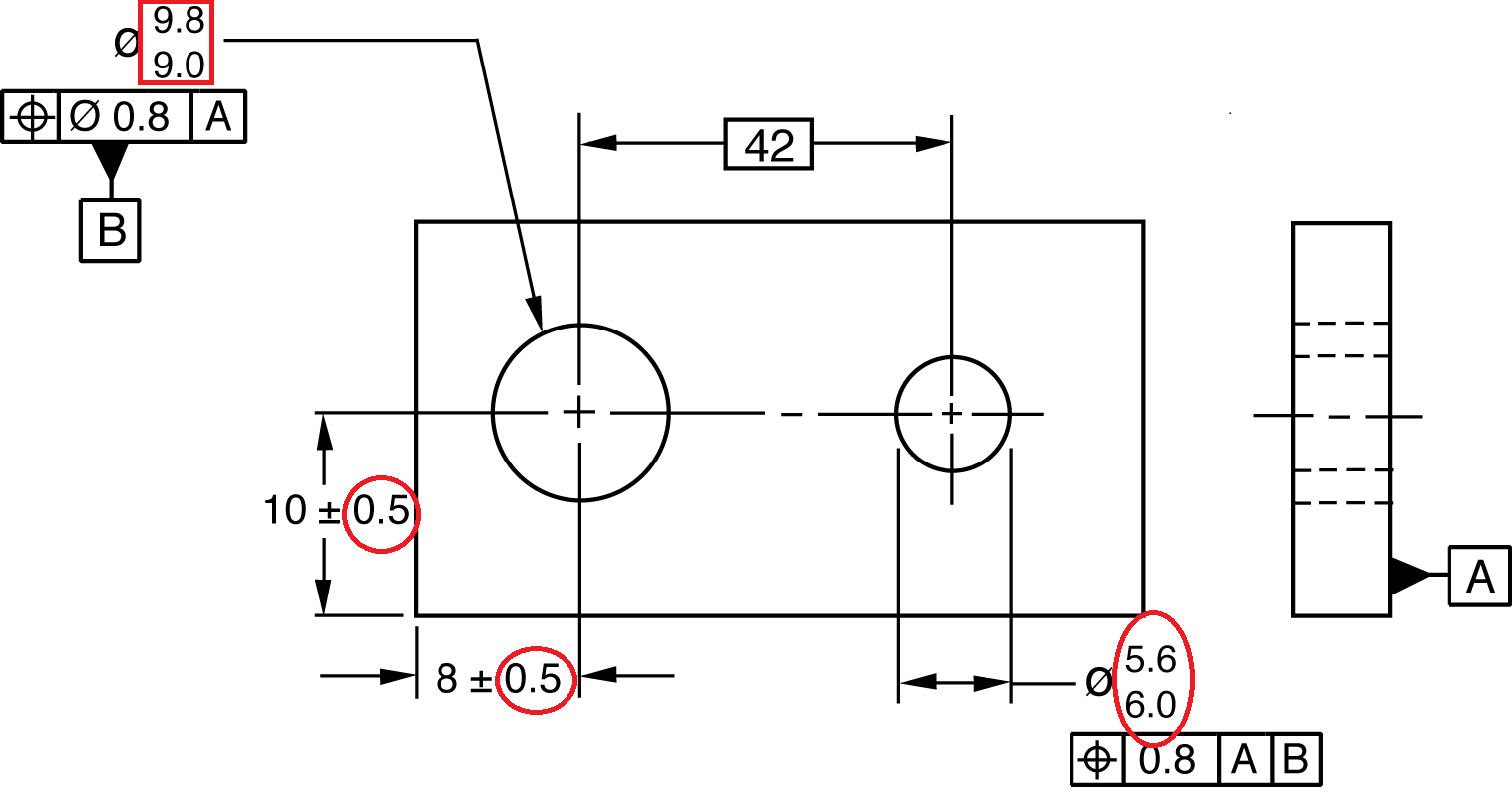

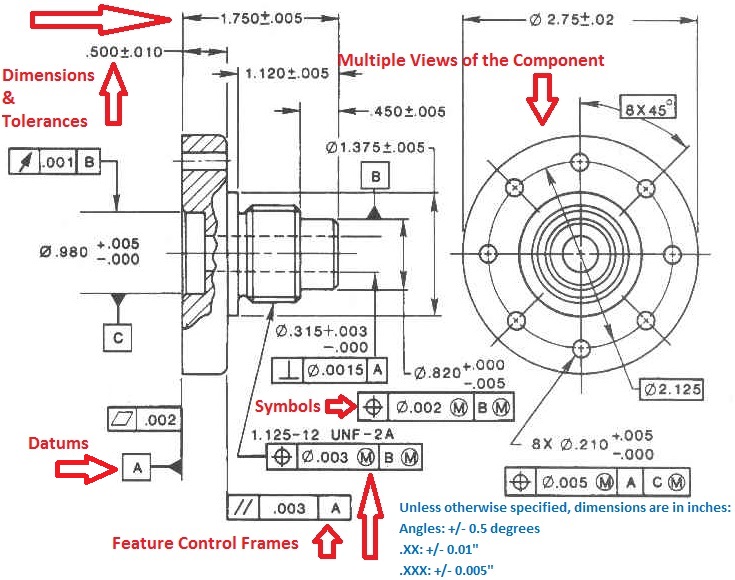

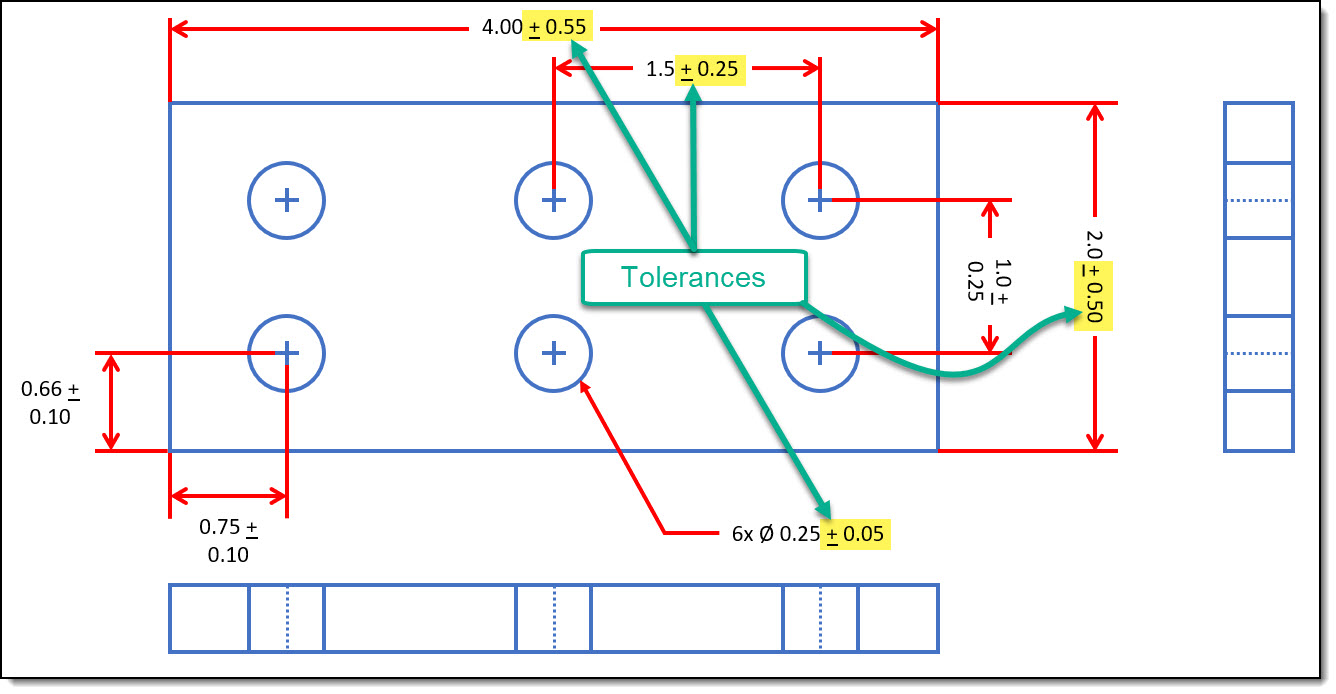

Tolerances In Drawings - Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Once the shape of a part is defined with an orthographic drawings, the size information is added also in the form of dimensions. You can check the tolerance chart below: Web all of the tolerances are less than zero, so they all have a zero before the decimal point. This video explains the basics of putting tolerances on dimensions in a technical drawing. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and engineering tolerances that helps engineers and manufacturers optimally control variations in manufacturing processes. Web a tolerance is defined as the acceptable range of dimensional variation that still allows for proper function. They can be applied to several conditions, including linear dimensions, angular dimensions, external radius, chamfer heights, etc. Knowing these limits is necessary for manufacturing and inspection. The dimension without tolerances is known as the basic. This video explains the basics of putting tolerances on dimensions in a technical drawing. You can check the tolerance chart below: Web tolerance is the total amount a dimension may vary and is the difference between the upper (maximum) and lower (minimum) limits. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. Because it is impossible to make everything to an exact size, tolerances are used on production drawings to control the parts. Refers to the acceptable variation in sizes like lengths, widths, thicknesses, radii, etc. As you can see, if drawing rules are properly followed, it is easy to quickly determine whether a drawing is dimensioned in inch or metric units. Knowing these limits is necessary for manufacturing and inspection. Because it is impossible to make everything to an exact size, tolerances are used on production drawings to control the parts. As you can see, if drawing rules are properly followed, it is easy to quickly determine whether a drawing is dimensioned in inch or metric units by looking for leading. Refers to the acceptable variation in sizes like lengths, widths, thicknesses, radii, etc. 19k views 3 years ago measurement and statistics. And the minimum value is called the minimum dimension. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and engineering tolerances that helps engineers and manufacturers optimally control variations in manufacturing processes. A comparison of dimensional versus geometric tolerances highlights the advantages of practicing geometric tolerancing. Knowing these limits is necessary for manufacturing and inspection. We will discuss below, several benefits of using tolerances. Basis of tolerances, deviations, and fits. Web geometric dimension and tolerance ( gd&t ) is a type of tolerance used along with linear tolerance to define nominal and allowable variations in the part geometry or an assembly. Web engineering tolerance is the permissible limit or limits of variation in: In upcoming articles, we will dive deeper into why tolerances are used and how they are defined, including the tolerancing methods shown in figure 4. The dimension without tolerances is known as the basic. Web and tolerancing the shapes and locations of features on objects. Web the proper way of defining the tolerances is to understand which dimensions are functional and which are not, how our dimensioning technic is adding up to the accumulation of the tolerances, which of our individual tolerances are influencing the most our accumulated tolerances, which of the tolerances we can make larger and. Web an engineering drawing may include general tolerances in the form of a table or just a little note somewhere on the drawing (e.g. Dimensioning a drawing also identifies the tolerance (or accuracy) required for each dimension.

Specifying Tolerance in Engineering Drawings Techno FAQ

Types Of Tolerance In Engineering Drawing at GetDrawings Free download

Engineering Drawings & GD&T For the Quality Engineer

It’s The Basics Of Engineering Tolerance.

Web All Of The Tolerances Are Less Than Zero, So They All Have A Zero Before The Decimal Point.

When Do We Need Tolerances?

Gd&T Is A Way Of Describing The Dimensions And Tolerances That’s Different From Traditional Coordinate Measurement Plus/Minus Tolerancing.

Related Post: