Tensile Drawing

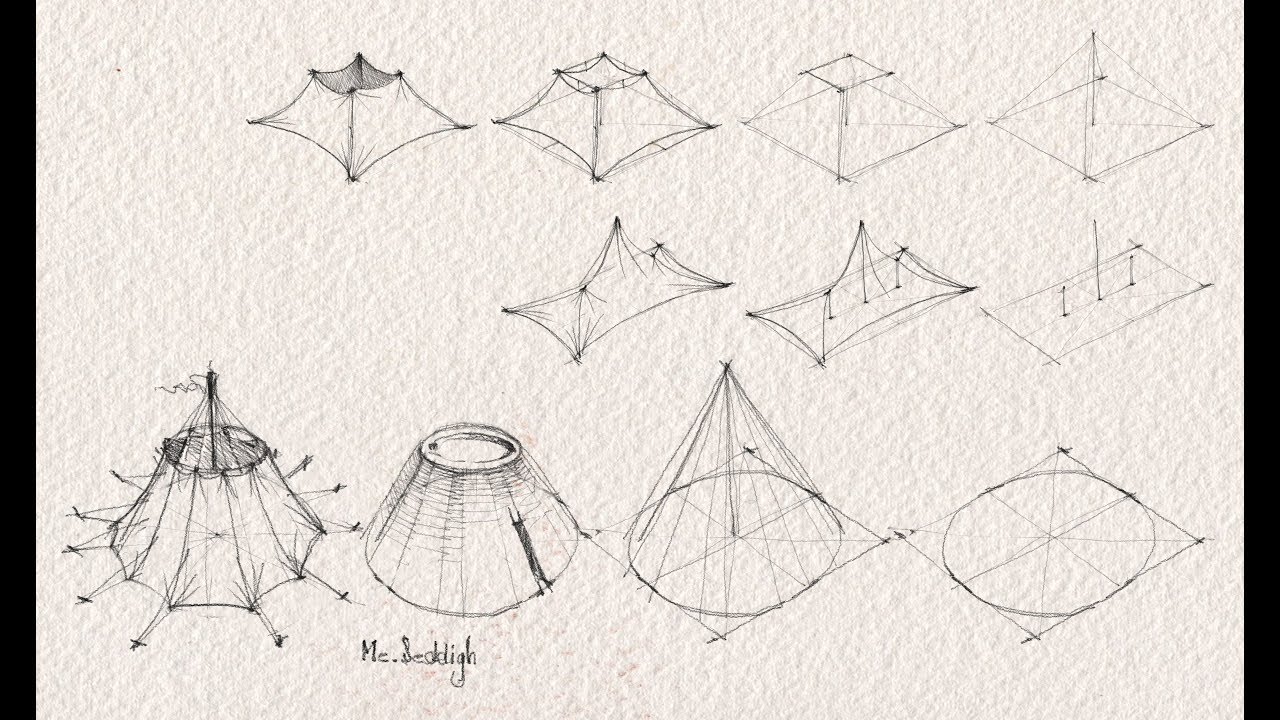

Tensile Drawing - Autocad drawing featuring comprehensive plan and elevation views of a tensile structure, also known as tensioned membrane structure or fabric structure. Web chosen liquids penetrate amorphous phase of polymers but do not influence their crystalline phase. In this article, we will explain in detail the principle of cold drawing, the effect of cold drawing on alloys and the cold drawing of different products. It was found that the more defective crystals were destroyed during drawing and rebuilt into more perfect crystals. 1.1 these test methods cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of area. Web under tensile drawing, crazing appeared to be the predominant process of plastic deformation in the equatorial regions, whereas profuse lamella fragmentation developed in the polar regions. Web the astm e8 / astm e8m standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area. The material broke in a relatively brittle manner at a strain of about 15%. The review focuses on the current studies of the deformation response and accompanying structural transformations of thermoplastic semicrystalline polymers subjected to uniaxial tension prior to the yield point. Study of the influence of laser energy density on the surface roughness of scalmalloy ® samples. Web tensile drawing behaviour of poly (ethylene terephthalate) f.rietsch†, r.a.duckett, i.m.ward. Cold drawing behaviour was observed at the lower temperatures and homogeneous deformation at 80°c. The tensile drawing behaviour of these fibers was then studied, either by drawing over a heated cylinder at 85°c or by drawing over both a heated cylinder and a plate at 180°c. It was found. The material broke in a relatively brittle manner at a strain of about 15%. Web the astm e8 / astm e8m standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area. Web comparison of tensile strength test. The material broke in a relatively brittle manner at a strain of about 15%. Though astm e8 / e8m measures many different tensile properties, the following are the most common: Study of the influence of laser energy density on the surface roughness of scalmalloy ® samples. The tensile drawing behaviour of these fibers was then studied, either by drawing over. Web chosen liquids penetrate amorphous phase of polymers but do not influence their crystalline phase. At λ = 22, however, 5 wt % of apao increased the tensile modulus. A detailed study has been undertaken of the drawing behaviour of poly (ethylene terephthalate) over the temperature range 20° to. The material broke in a relatively brittle manner at a strain of about 15%. The additives were extracted from compression molded samples by critical co 2. Web tensile drawing behaviour of poly (ethylene terephthalate) f.rietsch†, r.a.duckett, i.m.ward. Web drawing of tensile specimens according to astm e8/e8m. Autocad drawing featuring comprehensive plan and elevation views of a tensile structure, also known as tensioned membrane structure or fabric structure. Cold drawing behaviour was observed at the lower temperatures and homogeneous deformation at 80°c. Web a wide range of polyethylene terephthalate fibres was prepared by melt spinning to different degrees of molecular orientation. Study of the influence of laser energy density on the surface roughness of scalmalloy ® samples. The review focuses on the current studies of the deformation response and accompanying structural transformations of thermoplastic semicrystalline polymers subjected to uniaxial tension prior to the yield point. Instead of a typical increase in draw ratio with increasing temperature, the ptt draw ratio first increased, went through a maximum, and decreased; The limits of extensibility and orientation of poly (ethylene terephthalate) (pet) films are studied in drawing tests below and above the glass transition temperature. This cad resource provides detailed representations of the structure’s layout, showcasing its unique design elements, including fabric panels, and anchor points. Combinations of the two processes occurred in the diagonal regions.

Draw like an Architect Essential Tips basic shapes tensile

Sketch of different specimens a tensile, b torsion, c threepoint bend

tensile structures drawing Google Search Architecture details

Samples Whose Amorphous Phase Had Been Filled With Low Molecular Weight Molecules Remained Transparent Up To Rupture Without Evidencing Cavitation During Tensile Drawing.

Stanislav Patlazhan & Yves Remond.

Web Find The Latest Published Documents For Tensile Drawing, Related Hot Topics, Top Authors, The Most Cited Documents, And Related Journals.

Web Tensile Drawing Of Poly (Trimethylene Terephthalate) (Ptt) Was Studied At Room Temperature, 35, 50, And 75 °C.

Related Post: