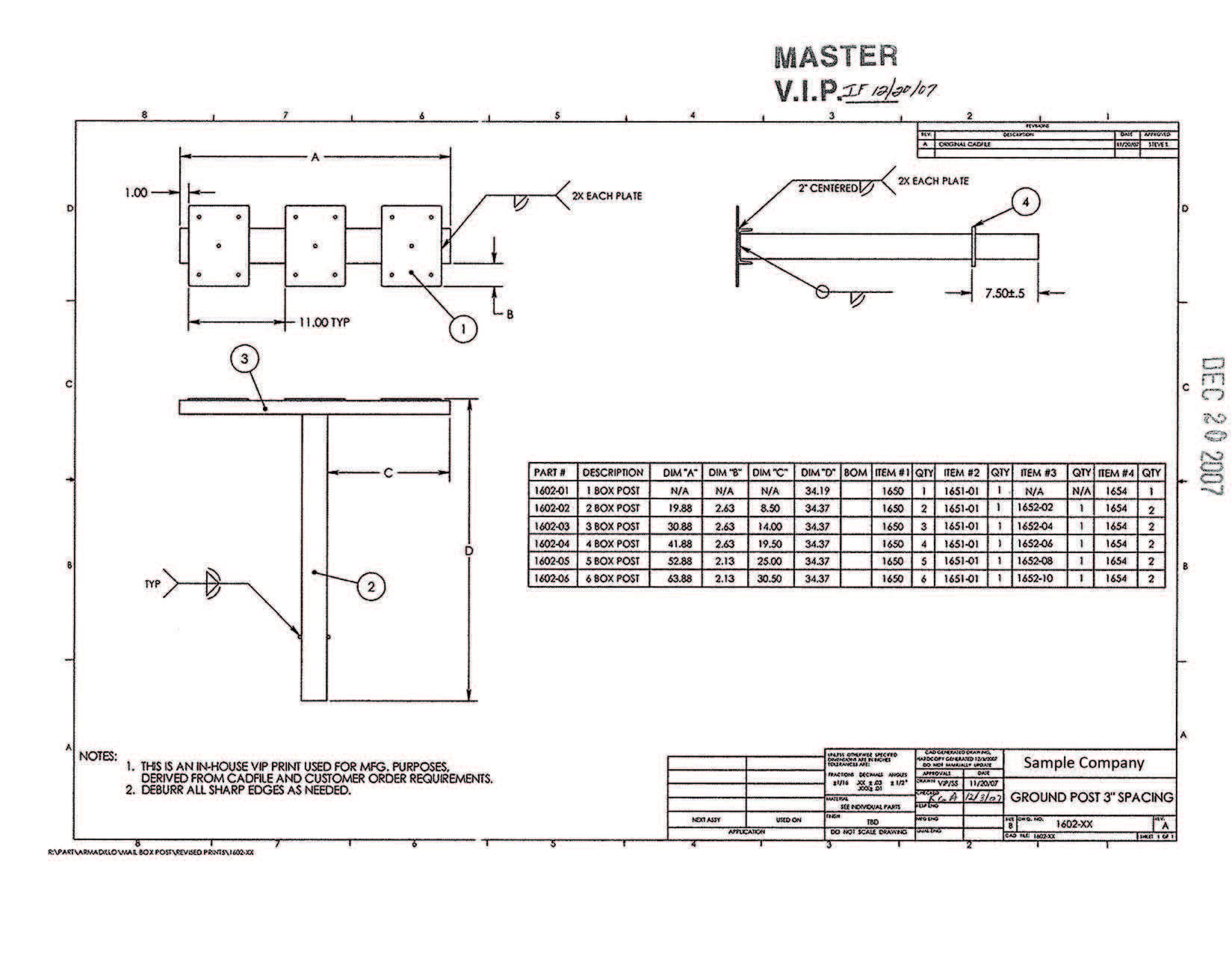

Sheet Metal Drawing

Sheet Metal Drawing - In this tutorial video we will learn how to sketch sheet metal drawings in solidworks with the help of sheet. When using the insert bends or convert to sheet metal features, apply the features as early Drawings of sheet metal parts can also contain views of the bent sheet metal part. Web 1 5 ways to optimize drawings for precision sheet metal fabrication services. Web sheet metal fabrication, metal stamping, deep drawing, stamping mold, metal welding, laser cutting, cnc punch, cnc bending, pipe bending In a part generated with the sheet metal tools, bend lines are stored in the flat pattern feature. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. The difference of a very small margin can result in something that fails, can’t be assembled, or simply doesn’t meet your expectations. 3d cad files are converted into machine code, which controls a machine to precisely cut. Blank holder force (bhf) is a crucial parameter in deep drawing, having close relation with the forming quality of sheet. Web for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Web reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. —sheet metal drafting is merely the application of the principles of ordinary mechanical. —sheet metal drafting is merely the application of the principles of ordinary mechanical drawing to objects which, for the purposes of drawing, lack thickness. The difference of a very small margin can result in something that fails, can’t be assembled, or simply doesn’t meet your expectations. Use the exact hardware name when possible; Sheet metal fabrication is the process of. These drawings are typically created by engineers or draftspersons and used by sheet metal fabricators to produce accurate and precise products. Sheet metal parts often require multiple manufacturing processes to produce correctly. Web preparing technical drawings for your sheet metal fabricator. It is a cut in a straight line across a strip, sheet or bar. Use the convert to sheet. Where to find bend lines. In a part generated with the sheet metal tools, bend lines are stored in the flat pattern feature. You can create *.dxf files of sheet metal flat patterns without creating a drawing. 4.3k views 3 years ago. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Because of this added complexity sheet metal drawings can be particularly tricky to create. It is a cut in a straight line across a strip, sheet or bar. This quick tutorial explains how. These drawings are typically created by engineers or draftspersons and used by sheet metal fabricators to produce accurate and precise products. Creating drawings of flat patterns. This chapter explains how to create sheet metal drawings. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. First, we need to know where the bend lines are stored/created/saved. Web for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Web preparing technical drawings for your sheet metal fabricator. 3d cad files are converted into machine code, which controls a machine to precisely cut.

Solidworks Tutorial Sheet metal drawings YouTube

Metal Drawings at Explore collection of Metal Drawings

Sheet Metal Drawing Pdf EASY DRAWING STEP

Web When Designing Sheet Metal Parts, The Order Preference For Use Of Feature Tools Are As Follows:

For Someone Who May Be Taking That First Step Into Having A Sheet Metal Design Created, Here Are The Essential Things That Your Drawing Needs Before Sending It.

Fig 1.—Pictorial Representation Of Anvil.

In This Tutorial Video We Will Learn How To Sketch Sheet Metal Drawings In Solidworks With The Help Of Sheet.

Related Post: