Sheet Metal Deep Drawing

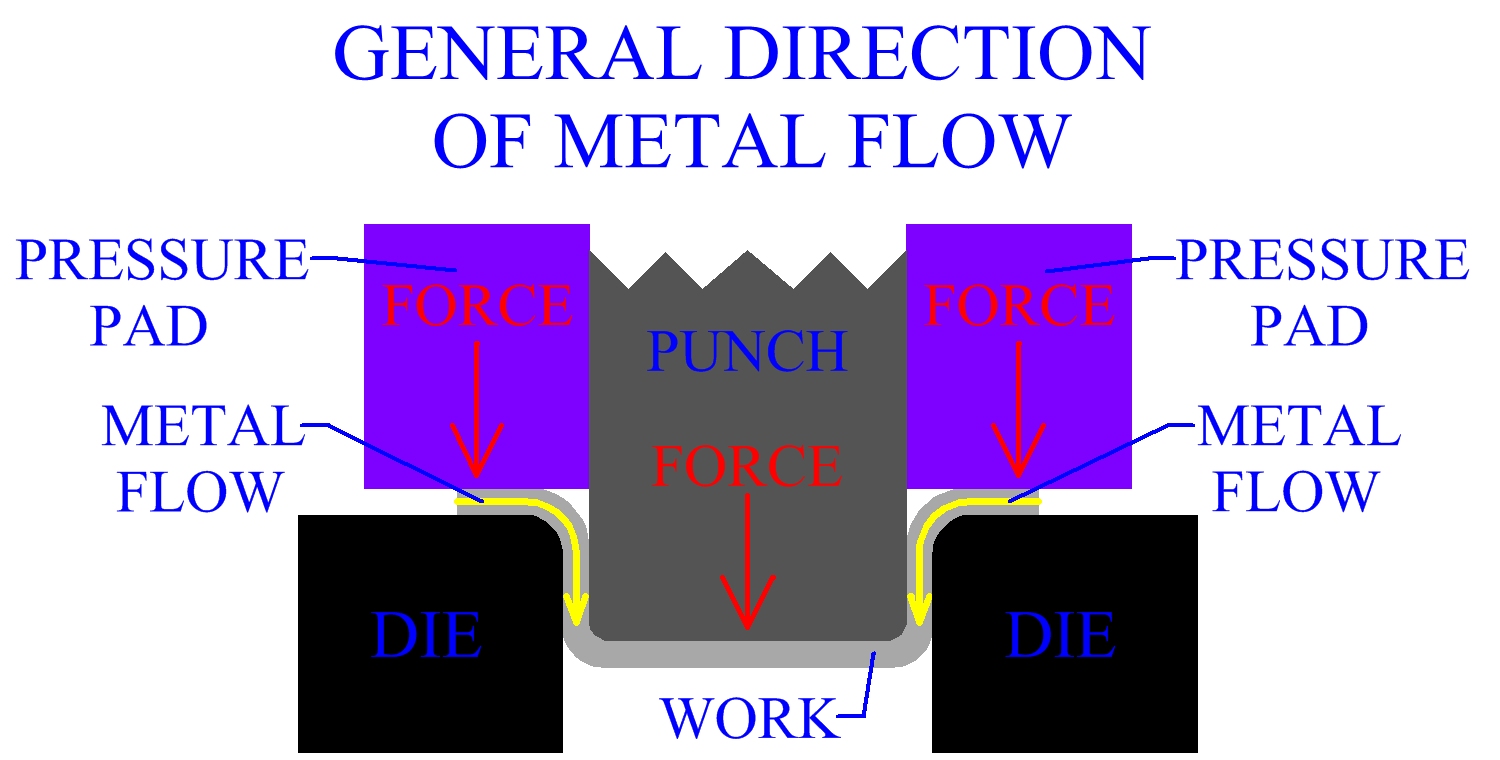

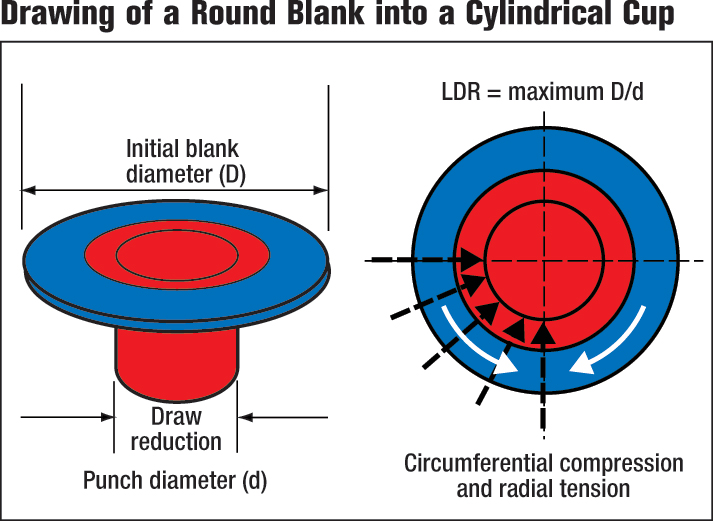

Sheet Metal Deep Drawing - Apart from its use in many other sectors, it is applied in the automotive industry for the. Usually executed using a punch, die, and. Explore amazon devicesdeals of the dayfast shippingread ratings & reviews [1] it is thus a shape. Web step 1—calculate blank sizes. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Cut to length a full width coil without. عملية السحب العميق للصاجin this video, we explore the fascinating world of deep drawing of sheet metal. Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Web what is deep drawing in sheet metal? Web deep drawing, a key fabrication technique that involves stretching metal sheets into desired shapes with a die and punch mechanism, is fundamental for creating high. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Usually executed using a punch, die, and. [1] it is thus a shape. Web custom manufacturer of. Cut to length a full width coil without. Web in general, deep drawing operates as a process of metal forming where the end goal is to create intricate parts with fine details. Materials include aluminum, malleable metal, brass, bronze, carbon steel, copper, kovar® & stainless steel. Web what is deep drawing? Deep drawing is a stamping process in which a. Deep drawing is a stamping process in which a flat sheet material is passed through a concave die under the pressure of a punch to. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Web custom manufacturer of deep drawn metal stampings. Apart from its use in. Web © 2024 google llc. Materials include aluminum, malleable metal, brass, bronze, carbon steel, copper, kovar® & stainless steel. Web sheet metal deep drawing. What is deep drawing in sheet metal fabrication? Usually executed using a punch, die, and. Web what is deep drawing? Web deep drawing is one of the most frequently used metal forming processes. Deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a. Web custom manufacturer of deep drawn metal stampings. Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape. Web step 1—calculate blank sizes. Web deep drawing, a key fabrication technique that involves stretching metal sheets into desired shapes with a die and punch mechanism, is fundamental for creating high. Web in the deep drawing process, when the size of sheet metal, the die, the lubrication, the drawing speed, the temperature, etc., have been determined, the blank holder force. Web deep drawing is one of the most widely used processes in sheet metal forming.

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

Deep Drawing from A to Z MetalForming Magazine Article

It Finds Application In Various Industries But Is Best Known For Its Use In The Automotive Industry.

Web Deep Drawing Forming Of Sheet Metal.

Web In General, Deep Drawing Operates As A Process Of Metal Forming Where The End Goal Is To Create Intricate Parts With Fine Details.

Deep Drawing Is The Process Of Converting A Blank Of Sheet Metal Into A Cylindrical Container With A Flat Or Hemispherical Base.

Related Post: