Rebar Drawings

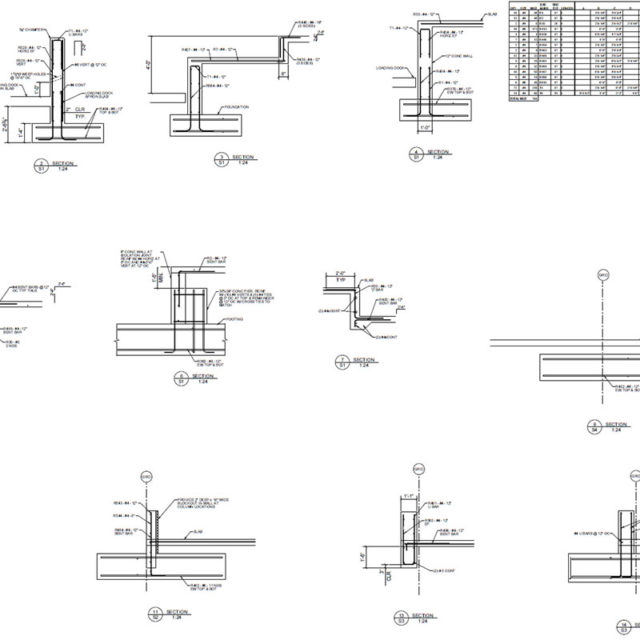

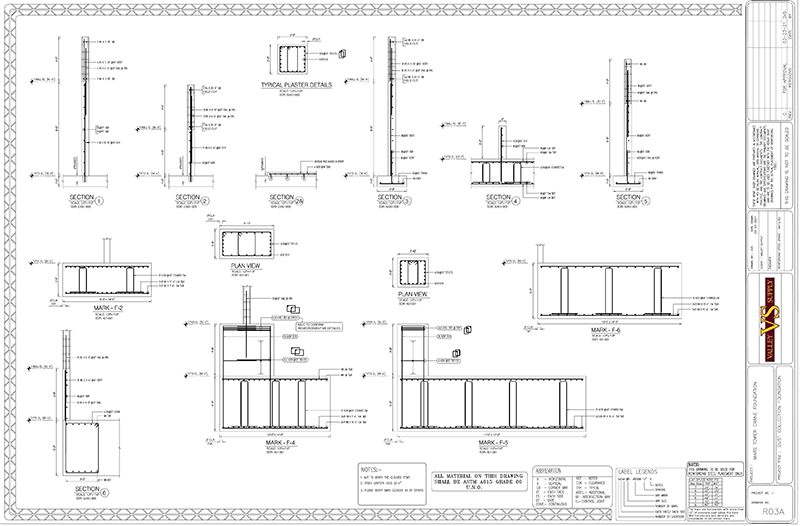

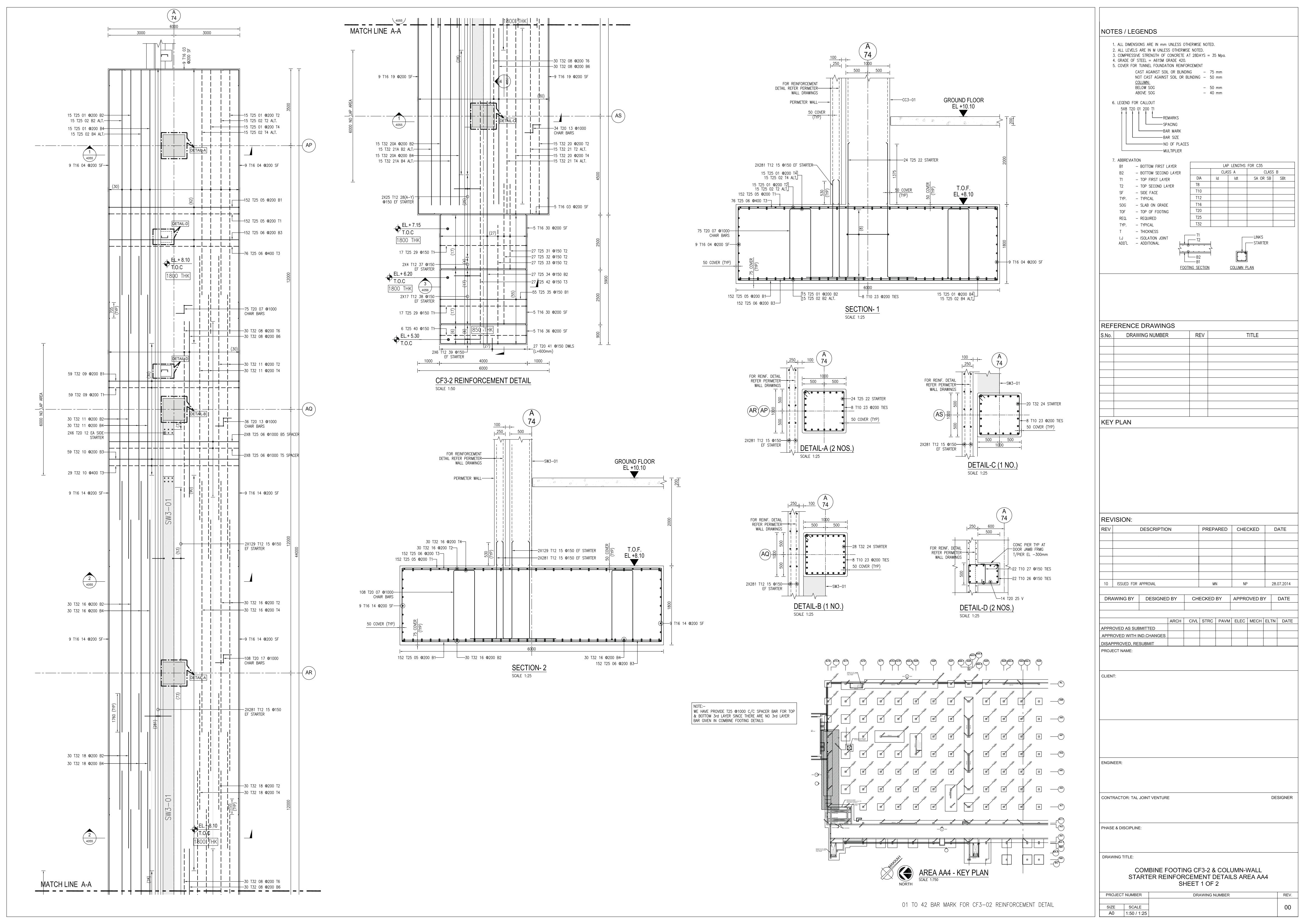

Rebar Drawings - Contact us today for more detail. Web a drawing approved by gbc engineers always requires verification and signature by the cad/bim engineer, team leader, qa engineer and project manager before being delivered. Web rebar detailing is the process of creating detailed drawings and schedules for the placement of reinforcing steel (rebar) in a concrete structure. This documentation and marking system helps provide a wealth of useful information about the manufacturing and composition of each bar of reinforcing steel. Web how to read rebar drawings in construction? Web rebar detailing is a detailed construction engineering process, usually done by the rebar fabricators, structural engineering consultants or the contractors to prepare a rebar placing drawing and a bar bending schedule. Rebar shop drawing for construction site. Easy to read for the field to reduce installation time and labor cost. Web rebar detailing with the most updated software. They are essential for both the fabrication and construction phases of a. Rebar shop drawing for construction site. Web rebar shop drawings are detailed drawings that provide information about the reinforcing steel used in a construction project. Web by prasad ·. With approved drawings, our rebar shop can expedite and ship your order shortly after. In this blog, oceanbim answers these questions for you and covers the solution to help you optimize. Key elements in rebar shop drawings. Annotating dimensions, quantities, and specifications. Web how to read rebar drawings in construction? Preparing the reinforcement drawings is an important task in the rebar detailing process. Rebar clashes with the neighbors' bars and structures. Our detailing team figures bends shapes and lap splices to meet the project specifications. Why are detailed formwork and rebar drawings important in the construction industry? Web in this drawing, we often see the structural connection details, the slab depression details, drop panel details, parapets, punching shear links, corbels, staircases details, and the actual rebar details in some of the. Rebar shop drawing for construction site. Key elements in rebar shop drawings. Web in this drawing, we often see the structural connection details, the slab depression details, drop panel details, parapets, punching shear links, corbels, staircases details, and the actual rebar details in some of the structural members, and the like. There are a number of ways to identify reinforcing bar (rebar) from the production mill to the fabrication shop to the jobsite. In this blog, oceanbim answers these questions for you and covers the solution to help you optimize for the project and much more… share post: Web rebar shop drawings are the blueprints that guide the placement of reinforcement bars within concrete structures. Web at whitacre rebar, our rebar detailers prepare shop drawings for the placement of the reinforcing steel. What are rebar schedules and codes? Your rebar design clashes with neighboring rebar detailed on a separate drawing. These drawings provide precise information on the placement, size, and shape of rebars in concrete structures. We specialize in smaller project, allowing us to turn around drawings in 7 to 10 days. Rebar shop drawings are an integral part of any construction project involving reinforced concrete. Web rebar detailing involves creating detailed shop drawings that specify the size, quantity, placement, and configuration of reinforcing steel bars (rebar) within concrete structures. Web rebar detailing is a detailed construction engineering process, usually done by the rebar fabricators, structural engineering consultants or the contractors to prepare a rebar placing drawing and a bar bending schedule. How to determine standard formwork and rebar drawings? Rebar clashes with the neighbors' bars and structures.

Rebar Drawing Steel Structural Consultant

Rebar Placement Drawings Valley Supply, Co.

Portfolio, Outsource Rebar Shop Drawing, Rebar Detailing and Estimating

Our Detailing Team Figures Bends Shapes And Lap Splices To Meet The Project Specifications.

Web A Drawing Approved By Gbc Engineers Always Requires Verification And Signature By The Cad/Bim Engineer, Team Leader, Qa Engineer And Project Manager Before Being Delivered.

Web By Prasad ·.

So In This Case, Mk605 Is A #6 Bar, And Likely Was The 5Th #6 The Drafter Drew.

Related Post: