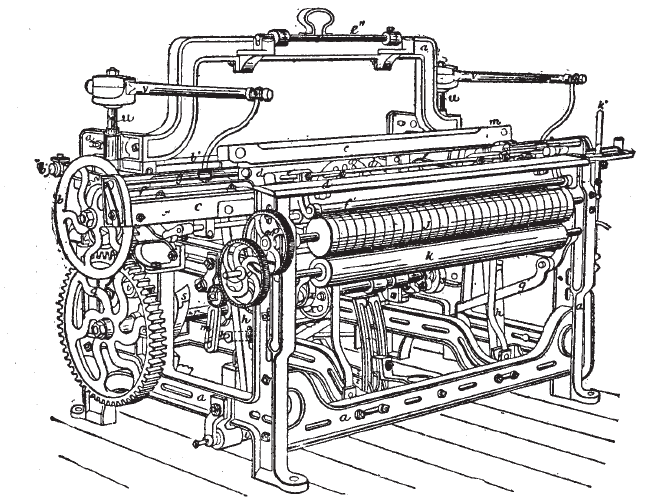

Power Loom Drawing

Power Loom Drawing - The first power loom, a mechanized loom powered by a drive shaft, was designed in 1784 by edmund cartwright and first built in 1785. Web a power loom is a loom powered by a source of energy other than the weaver's muscles. Web manager dave roberts acknowledged ohtani's exceptional talent, drawing comparisons to power hitters like giancarlo stanton and aaron judge. The yarn in the vertical direction is referred to as a warp or end [ 1]. Different parts of loom with identification: A loom contains different parts. [ digital file from b&w film copy neg. A complete online tutorial for power loom designing with step by step procedures 0422 435 55 33 | banarasdesigns@gmail.com Loom weaving kevlar fabric in carbon fibre factory. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. Unable to buy drawings or a model of a power loom, he committed the power loom design to memory. Pencil, pen, sepia and wash, 12x19cm. A complete online tutorial for power loom designing with step by step procedures 0422 435 55 33 | banarasdesigns@gmail.com Loom weaving kevlar fabric in carbon fibre factory. Web here's how to use the drawing tool: (the american textile museum, lowell, mass., usa) A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early industrial revolution. As innovation continued throughout the industrial revolution, significant inventions shaped history. ] full online access to this resource is only available at the library of congress. Web unveiling the. (the american textile museum, lowell, mass., usa) The first power loom was designed and patented in 1785 by edmund cartwright. It is the process of separating the warp yarn into two layers to form a tunnel which is called shed, which is known as shedding. Web the complete set of patent drawings as reproduced in the first printing of cartwright's. [ digital file from b&w film copy neg. It is the process of separating the warp yarn into two layers to form a tunnel which is called shed, which is known as shedding. Most cloth is now woven on power looms, but some is still woven on handlooms. The power loom reduced demand for skilled. Web 3 take up roller, wooden, driven by some sort of a slipping clutch arrangement, take the cloth from the guide roller. Cross section of shuttle loom with identification. Upon his return to boston, he recruited master. Original of a plate from baines' history of cotton manufacture 1836. Web photo, print, drawing power loom weaving. When power looms were developed, other looms came to be referred to as handlooms. A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early industrial revolution. The first power loom, a mechanized loom powered by a drive shaft, was designed in 1784 by edmund cartwright and first built in 1785. (the american textile museum, lowell, mass., usa) The fabric path is over the top of the friction roller around it until it almost touches the bottom of the fabric then over the guide roller and down to the take up roll. Pencil, pen, sepia and wash, 12x19cm. Traditional handlooms were slow and required several laborers to operate.

Understanding Weaving What Are Looms?

Power Loom 3D Model Sketchup Telar 3d model, Power loom, Power

Power Loom by Edmund Cartwright Concepção, Design

] Full Online Access To This Resource Is Only Available At The Library Of Congress.

Using His Contacts, He Visited A Number Of Mills In England, Sometimes In Disguise.

Different Parts Of Loom With Identification:

The Yarn In The Vertical Direction Is Referred To As A Warp Or End [ 1].

Related Post: