Moulds Drawing

Moulds Drawing - The mold for deep drawing is been called deep drawing die. Web 11 audit procedures for mold drawing. We are going to look at the things that one has to consider when mold drawing and designing or injection molding process and how each of these considerations affects the final end product. Web the injection mold design tutorial is the best guide there is for the money. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Ejector pins type and locations. Web choose from 1,860 mold drawing stock illustrations from istock. Placement of lifters and sliders. Web gathering materials for mold making. Before starting the mold making process, it's crucial to gather all the necessary materials. This type of drawing is often used in the manufacturing industry to develop prototypes of ongoing products in a plan using a mould. Join the grabcad community today to gain access and download! Injection mold standard, mold series, common mold steels and applications, drawing format and standards, geometry format, construction, and standards. Web the injection mold design tutorial is the. Types of deep drawing parts. This will make it easy to separate the mold into several pieces at the appropriate time. This section will guide you through the essential tools and materials required for mold making. Contact us today to start your custom molding project. Web gathering materials for mold making. Materials with high viscosity and large shrinkage are more likely to adhere to the mold core, so a larger draft angle is required. Web what is an injection molding dfm (design for manufacturing) report? Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured. Join the grabcad community today to gain access and download! The role of an injection molding dfm report. Materials with high viscosity and large shrinkage are more likely to adhere to the mold core, so a larger draft angle is required. Whether you're a beginner or an experienced artist, our guide will help you master the art. Web the injection mold design tutorial is the best guide there is for the money. Web the mold structure drawing typically includes a front view, top view, and side view, providing a complete view of the mold’s structure. We are going to look at the things that one has to consider when mold drawing and designing or injection molding process and how each of these considerations affects the final end product. 2.1.5.2 drawings shall be complete in size, correct, clear and reasonable, without missing. Web 2.1.5.1 product benchmarks shall be noted in drawings, and dimensions shall be marked on a uniform basis. Web choose from 1,860 mold drawing stock illustrations from istock. Dec 8, 2022 | blog, mold design dips. Designing plastic parts is a complex task involving many factors that address application requirements. Web as shown in the table, we can draw two conclusions, 1. This section will guide you through the essential tools and materials required for mold making. Having a proper tool design review and checklist can and will save time to market. The height of the ribs can increase the stiffness of the injection molded part in a geometric progression.

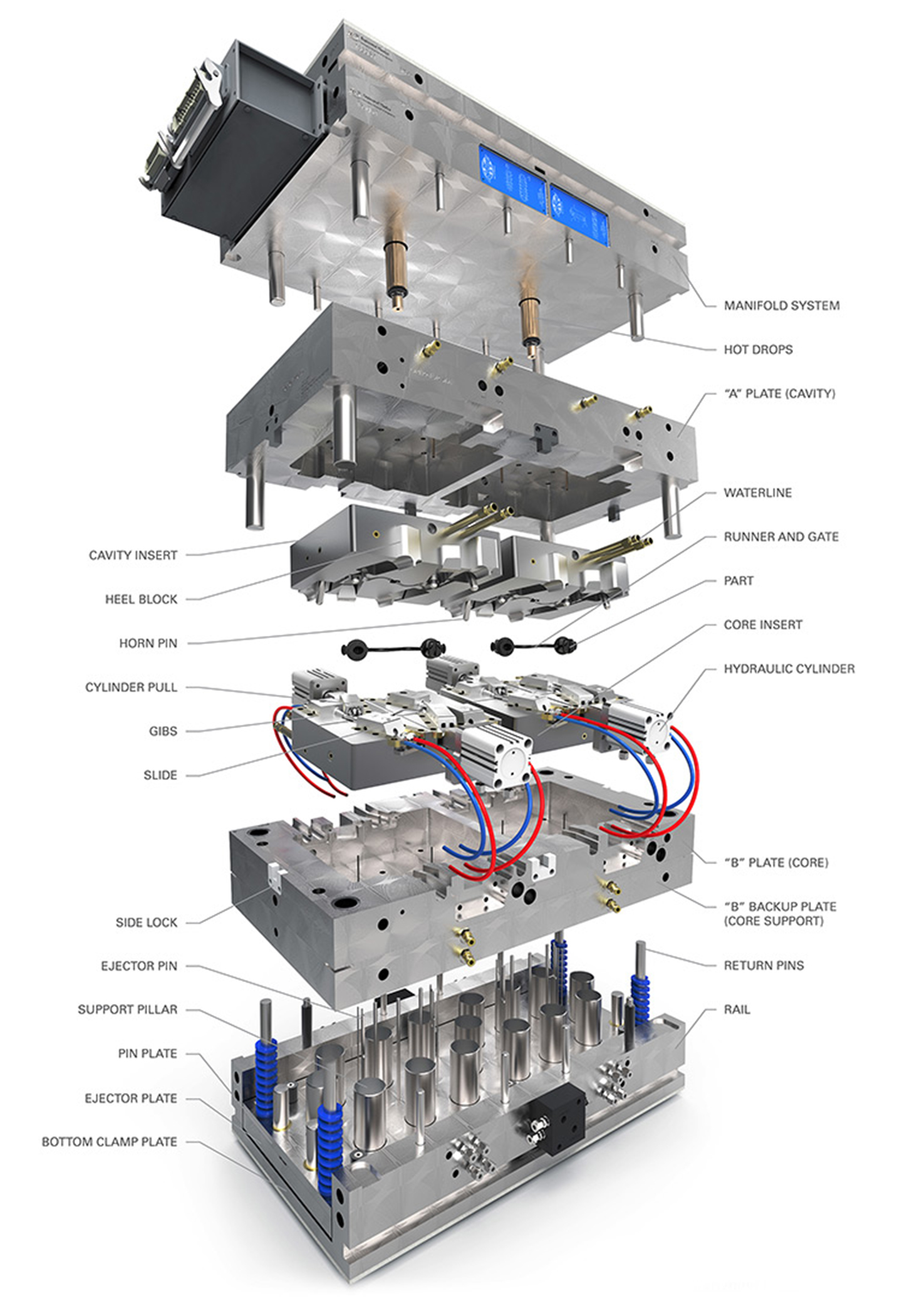

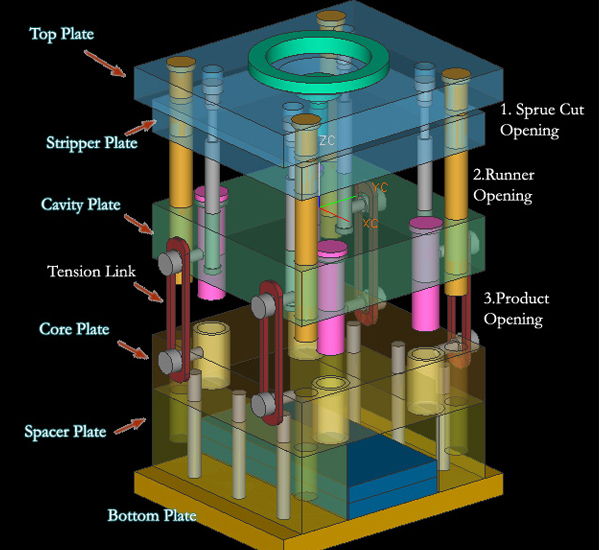

Injection Mold Diagram

Anatomy of a Mold PTI Engineered Plastics, Inc.

Six Points Of Preparation For Mold Assembly China Plastic Injection

This Includes Creating 2D Or 3D Drawings Of The Mold, Determining The Number Of Cavities Needed, And Deciding On The Type Of Mold (Single Or.

Ejector Pins Type And Locations.

Web Basics Of Injection Molding Design.

There Are A Variety Of Mold Types For Different Applications:

Related Post: