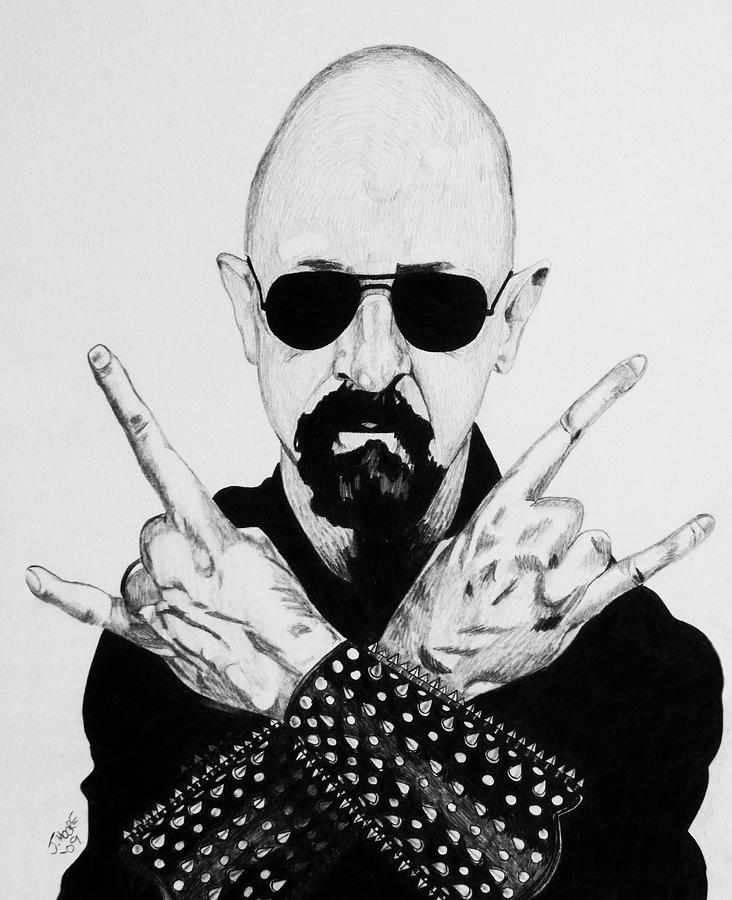

Metal Drawing

Metal Drawing - Web learn about metal drawing and specifically the deep drawing process, a popular form of metalwork. The winning numbers were 2, 8, 28, 31, 32 and 41. Metal flow patterns in metal drawing operations. Chief billy kelley said workers were grinding metal when some of the sparks. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes. Web drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. Web the ultimate guide to metal deep drawing. Deep drawing quality analysis and control. Analysis of deep deformation process. 1.1 deep deformation process and characteristics. Web learn about metal drawing and specifically the deep drawing process, a popular form of metalwork. Web according to chief billy kelley, contractors were grinding metal at station 2 on 42nd avenue when sparks ignited a fire. Change your metal type with a gradient map! The procedure is generally carried out cold to guarantee precise tolerances, enhanced grain structure and. During drawing, the material is fed through a series of dies or dies with progressively smaller hole sizes. This process is very similar to metal extrusion, the difference being in the application of force. Metal flow patterns in metal drawing operations. The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through. True drawing results in very little stretching of the metal. Web drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. Drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Perhaps one of the biggest misconceptions about deep drawing is that. Change your metal type with a gradient map! Web metal drawing, by definition, is the process of stretching metal material and forming it using tensile, or pliable, force. The process of drawing metal wires, rods, and bars is a crucial technique in the manufacturing industry. The intricacies of metal drawing. To know more about metal drawing, read the article thoroughly. Web metal drawing is a machining process used to reduce the diameter of a metal material, such as wire or tubing, through the application of controlled tensile forces. What is a gradient map? Drawing is classified into two types: Metal drawing is a metalworking process where a workpiece is pulled through a die to reduce its diameter and increase its length. Web built with meta llama 3, meta ai is one of the world’s leading ai assistants, already on your phone, in your pocket for free. The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. Tubes and shapes are typically cold drawn, which ensures accurate tolerances, improved material properties, and enhanced grain structure and surface finish. 1.1 deep deformation process and characteristics. Web learn about metal drawing processes and how they permanently deform metal into 3d shapes. Sheet metal drawing and wire, bar, and tube drawing. Deep drawing quality analysis and control.![How To Draw Metal [Drawing Tips] Metal drawing, Ink drawing](https://i.pinimg.com/originals/eb/17/39/eb1739b95291295ec4e039060265f1ff.jpg)

How To Draw Metal [Drawing Tips] Metal drawing, Ink drawing

How to draw a metal ingot aluminium aluminum

Metal Drawings at Explore collection of Metal Drawings

Perhaps One Of The Biggest Misconceptions About Deep Drawing Is That The Metal Is Stretched Into The Part Geometry.

Web Metal Drawing Is A Process That Stretches And Pulls Wire And Bar Metal Tube Through Direct Tensile Force To Reduce Its Diameter And Increase Its Length.

This Process Is Very Similar To Metal Extrusion, The Difference Being In The Application Of Force.

Widely Used In Various Industries, Such As Automotive, Aerospace, And Construction, Metal Forming Encompasses A Diverse Range Of Methods,.

Related Post: