Deep Draw Forming

Deep Draw Forming - When deciding how to get parts or products made for your company you need to make sure you’re picking the. [1] it is thus a shape transformation process with material retention. It allows for superior quality components, produced at high. In sheet hydroforming, a metal. Web the core idea behind sheet metal drawing revolves around the concept of plastic deformation. Learn about the types, tools, and applications of deep. Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Deep drawing and press forming. Find out the factors that affect the quality and efficiency of deep. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawing is a sheet metal forming process that occurs under tensile and compressive conditions. Web deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. In the more common deep drawing process, the product as a whole presents an axisymmetric circumferential shape, and the material is uniformly. Find out the key elements affecting metal flow, such as. When deciding how to get parts or products made for your company you need to make sure you’re picking the. Web deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. Unlike elastic deformation, where a material returns to. The article explains the basic metal flow concept, the draw. Unlike elastic deformation, where a material returns to its original state after. Web deep drawing is a sheet metal forming process that occurs under tensile and compressive conditions. Web deep drawing is the process of transforming a flat sheet of steel into a deep shape by drawing from the edges. Web deep drawing is a form of metal stamping where the depth of the draw is typically greater than its diameter. In the more common deep drawing process, the product as a whole presents an axisymmetric circumferential shape, and the material is uniformly deformed. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web learn how to design, build, and troubleshoot deep drawing stamping dies for various materials and part shapes. This basic procedure provides the foundation for. Web macrodyne 300 ton deep draw press deep drawing 101 introduction what is deep drawing deep drawing is a metal forming process for creating seamless, sheet metal. Web the core idea behind sheet metal drawing revolves around the concept of plastic deformation. Finding the best deep drawn metal supplier to. Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Learn how to design and predict. It is useful for creating cylindrical, seamless, and complex parts. Web deep drawing is a sheet metal forming process that occurs under tensile and compressive conditions. When deciding how to get parts or products made for your company you need to make sure you’re picking the. Web deep drawing is the process of transforming a flat sheet of steel into a deep shape by drawing from the edges and sucking in the material. Web deep drawing is a metal forming process that involves using dies to form metal blanks into deeper shapes. Deep draw forming with conventional tool and die technology is the stretching of sheet metal stock, commonly.

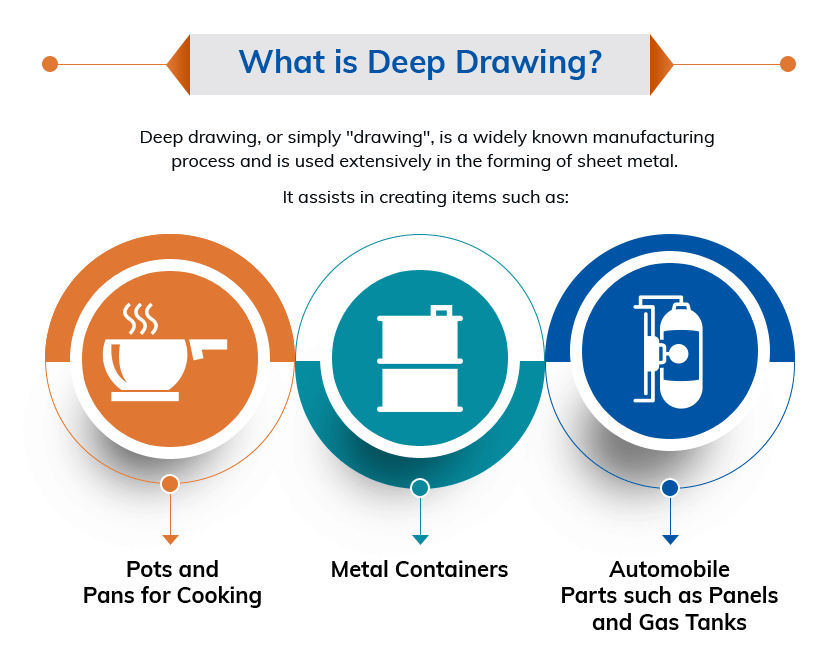

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep Draw Process Precision Manufacturing Capabilities by PMP

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

It Allows For Superior Quality Components, Produced At High.

Deep Drawing And Press Forming.

Learn About The Types, Tools, And Applications Of Deep.

Web Learn What Deep Drawing Is, Its Advantages, When To Use It, And How To Design And Set Up A Deep Drawn Part.

Related Post: